Absolutely hygienic conditions are necessary for the entire production cycle of pharmaceutical and ultra high

industries. Therefore Tubes and Fittings with a smooth internal surface and extensively installed with the

advantages of cleaning easily and avoiding bacteria contamination.

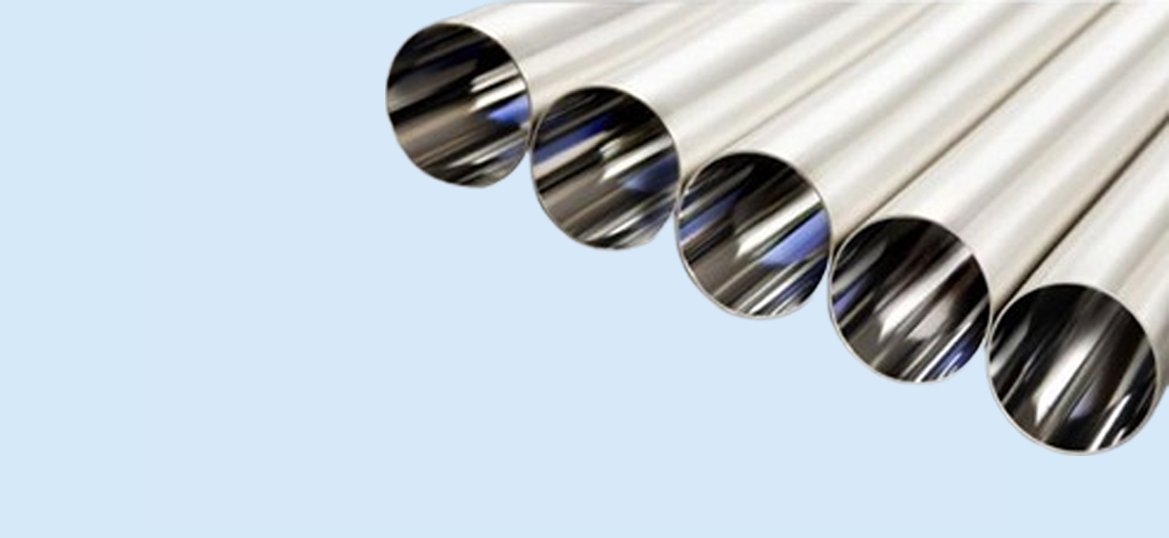

According to to the ASME BPE Specification Tubes Grade with ASTM SS316L content low Sulphur of 0.005% to

0.017% in surface finish of SF1 & SF4.

CSE only offers tubes that are manufactured, quality controlled,

marked, and certified according to the highest standards for hygienic

equipment design and guarantees extended quality and trace

ability.

CSE BPE tubing significantly reduces inspection requirements prior to

installation by utilizing only the highest quality stainless steel materials.

CSE delivers directly from stock the following stain less steel tubes in

grade TP316L with low sulfur content of 0.005% to 0.0017% and SF1

and SF4 finishes (according to the ASME BPE specification)

CSE BPE EP products with following advantages:

Homogeneously EP layer to minimize rouging

Higher chrome concentration for better corrosion resistance"

Guaranteed smoothness of all internal surfaces to reduce Bio film"

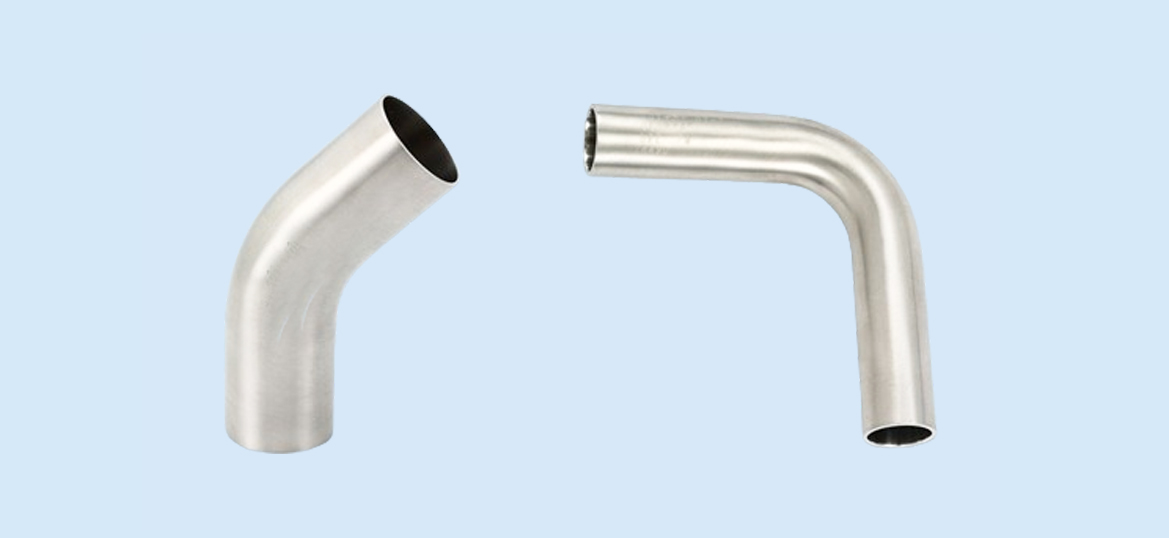

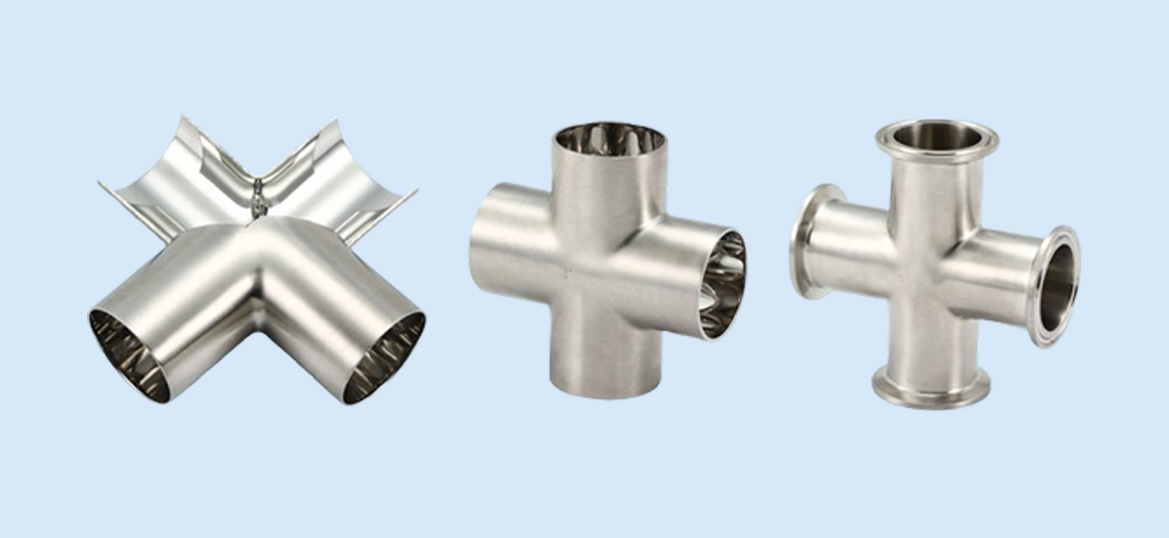

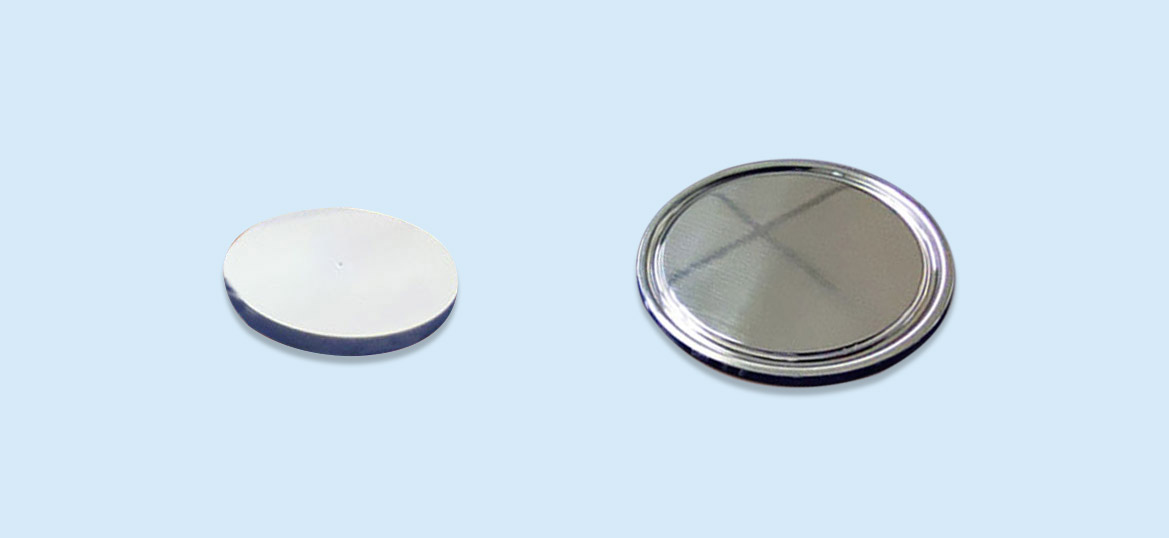

We have wide range in Elbow, TEE, Reducers, TC Ferrule, Clamp, etc. in BPE,3A,DIN, BS, SMS.

1) ID/OD polishing

2) Only ID polishing

3) Only OD polishing

4) unpolished

Roughness: #400, #320, #240, #180............

Ra < 0.8 μm, 0.6 μm, 0.5 μm, 0.4 μm........(Other Surface finished can be ordered)

CSE Sanitary tubes for Pharmaceutical, Semiconductor, Cosmetic, Food and Dairy Industry etc.

Material : ASTM 304, 304l, 316l

Spec : ASTM A269, A270

Surface & Roughness :

1) OD/ID Pickle ( Ra ≤ 1.0 μm)

2) Polished :

1) ID Polished to 180Grit ( Ra ≤ 0.8 μm)

2) ID Polished to 240Grit ( Ra ≤ 0.6 μm)

| BPE Standard | 3A STANDARD | SMS STANDARD | DIN 11850 / 11865 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | OD | T | Size | OD | T | Size | OD | T | Size | OD-DB | OD-DA | OD (11865) | T |

| 1/4" | 6.35 | 0.89 | 1/4" | 6.35 | 1.245 | - | - | - | DN6 | - | - | 8 | 1 |

| 3/8" | 9.53 | 0.89 | 3/8" | 9.525 | 1.245 | - | - | - | DN8 | - | - | 10 | 1 |

| 1/2" | 12.7 | 1.65 | 1/2" | 12.7 | 1.65 | - | - | - | DN10 | 12 | 13 | 13 | 1.5 |

| 3/4" | 19.05 | 1.65 | 3/4" | 19.05 | 1.65 | - | - | - | DN15 | 18 | 19 | 19 | 1.5 |

| 1" | 25.4 | 1.65 | 1" | 25.4 | 1.65 | - | - | - | DN20 | 22 | 23 | 23 | 1.5 |

| 1.5" | 38.1 | 1.65 | 1.5" | 38.1 | 1.65 | DN25 | 25 | 1.25 / 1.5 | DN25 | 28 | 29 | 29 | 1.5 |

| 2" | 50.8 | 1.65 | 2" | 50.8 | 1.65 | DN38 | 38 | 1.25 / 1.5 | DN32 | 34 | 35 | 35 | 1.5 |

| 2.5" | 63.5 | 1.65 | 2.5" | 63.5 | 1.65 | - | - | - | DN40 | 40 | 41 | 41 | 1.5 |

| 3" | 76.2 | 1.65 | 3" | 76.2 | 1.65 | DN50 | 51 | 1.25 / 1.5 | DN50 | 52 | 53 | 53 | 1.5 |

| 4" | 101.6 | 2.11 | 4" | 101.6 | 2.1 | DN63 | 63.5 | 1.5 | DN65 | 70 | 70 | 2 | |

| - | - | - | 5" | 127 | 2.77 | DN76 | 76.1 | 1.6 / 2 | DN80 | 85 | 85 | 2 | |

| 6" | 152.4 | 2.77 | 6" | 152.4 | 2.77 | DN100 | 101.6/104 | 2 | DN100 | 104 | 104 | 2 | |

| - | - | - | 8" | 203.2 | 2.77 | - | - | - | DN125 | 129 | 129 | 2 | |