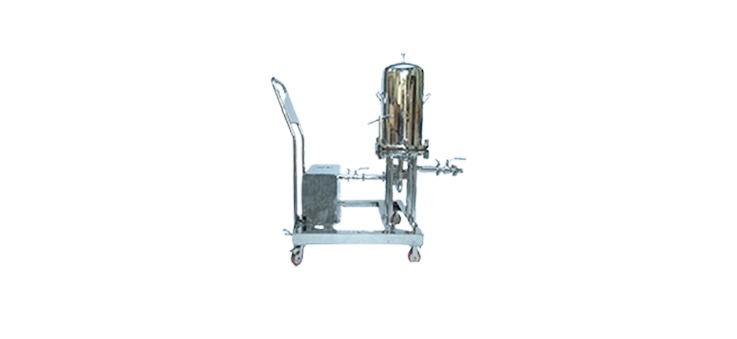

- SS filter housings are ideal for sterile filtration applications. These single and multi round sanitary filter housings include a positioning plate, positioning plate retainer rods, vent and drain connections, silicon 'o'- ring or gaskets and sanitary gauge port.

The filter housing are used to protect the sensitive components of the control system and odorant injector.

- Exclusively designed to ensure meeting all the pharmaceuticals industry housing applications.

- Customization according to process requirement.

- Flow efficient design with low pressure drop.

- Steam jacketed and electrically heated housing with option of integrity test.

- User friendly vertical design with sanitary connection.

- CIP and SIP design.

- Easy draining features, including downward sloping internal contour and low point drain.

- Fewer welds – extremely sanitary design.

- Requires mimnimum floor space and quickly dismantles for easy cleaning.

- Cartridge locks into place assuring secure installation.

- Automated orbital welding – produces consistent high quality welds.

- T-style and inline configurations allow flexible piping options.

- Chemical certificate, dimensional certificate, raw material traceability, hydro test certificate.

- Dedicated engineering team for product development and efficiency optimization.

- Customization according to process requirement.

- Flow efficient design with low pressure drop.

- Steam jacketed and electrically heated housing with option of integrity test.

- User friendly vertical design with sanitary connection.

- CIP and SIP design.

- Easy draining features, including downward sloping internal contour and low point drain.

- Fewer welds – extremely sanitary design.

- Requires mimnimum floor space and quickly dismantles for easy cleaning.

- Cartridge locks into place assuring secure installation.

- Automated orbital welding – produces consistent high quality welds.

- T-style and inline configurations allow flexible piping options.

- Chemical certificate, dimensional certificate, raw material traceability, hydro test certificate.

- Dedicated engineering team for product development and efficiency optimization.

| Technical Data | |

|---|---|

| No. Of Cartridges | Up to 25 Nos, (Customizable as per requirement). |

| Cartridge Lengths | 5”, 10”, 20”, 30”, 40”. |

| Flow Rate | Up to 100 m³/hr , (Customizable as per requirement). |

| Cartridge Fitment | Plug - in. |

| Design Code | ASME section VIII Division 1. |

| MOC | Stainless Steel Grade - 304, 304L, 316, 316L, Hastelloy C |

| Pressure Rating | 1 bar – 15 bar. |

| Temperature Rating | 25°C to +65°C more on request. |

| Connection Size | ½” – 4”. |

| Connections | Flange, Tri-Clover Clamp, Socket. |

| Sealing Material | EPDM, Silicon, Viton, PTFE. |

| Lifting Device | Lifting Handle, Lifting Lug. |

| Vessel Support | Legs, Tripod. |

| Surface Finish | Internal <= 0.38µm Ra and External <=0.5µm Ra, as per requirement. Electro Polished / Matt Finish. |