Sparkler Filter

"The Sanitary Sparkler Filter is the ultimate solution for achieving exceptional clarification in your process liquids. Engineered with precision and reliability in mind, this high-performance product utilizes advanced depth filtration technology to effectively remove unwanted solids, colloids, and contaminants from your liquid streams, guaranteeing consistently high-quality results

Designed for versatility and efficiency, the Sanitary Sparkler Filter is suitable for a wide range of applications across various industries, including pharmaceuticals, food and beverage, cosmetics, and chemicals. Whether you're processing liquids for production, purification, or polishing purposes, this innovative filtration system delivers unparalleled performance and reliability.

Working Principle:

"The sparkler filter works by passing fluid through a filter medium. This medium trap particle larger than the filter's pore size, removing suspended solids, colloids, and contaminants from the fluid. Under pressure, the clarified liquid flows out of the filter, leaving behind a filter cake of retained solids on the medium's surface."

Key Features:

- Advanced Depth Filtration: Utilizes a multi-layered filter media to capture and retain contaminants, ensuring superior clarification.

- Sanitary Design: Constructed with sanitary-grade materials and finishes to meet the stringent hygiene requirements of sanitary processing environments.

- Easy Maintenance: Features a user-friendly design for quick and hassle-free filter media replacement and cleaning procedures.

- Robust Construction: Engineered for durability and longevity, with high-quality components that withstand demanding operating conditions.

- Scalable Solutions: Available in a range of configurations to meet your specific flow rate and capacity needs.

Benefits:

- Consistent Quality: Achieve consistently high-quality liquid products by removing impurities and contaminants.

- Improved Efficiency: Enhance production efficiency and minimize downtime with reliable and efficient filtration performance.

- Compliance: Ensure compliance with stringent sanitary and regulatory requirements for product purity and safety.

- Cost Savings: Reduce product losses, rework, and waste, leading to significant cost savings over time.

- Customization Options: Available in various sizes, configurations, and materials to suit specific application requirements.

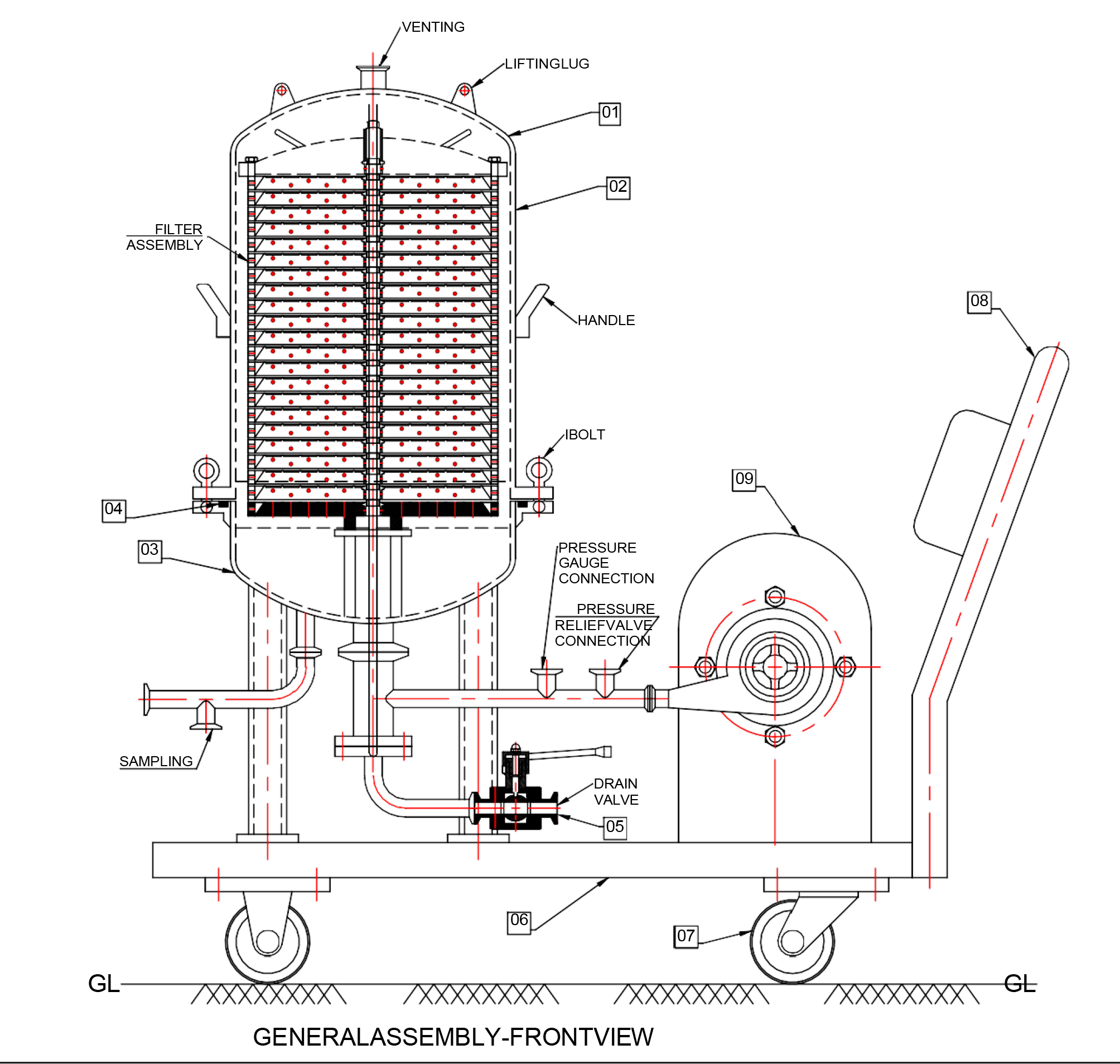

| PARTNO | DESCRIPTION | M.O.C. | QTY. |

|---|---|---|---|

| 01 | TOPDOME- DISH | SS316L | 01NO. |

| 02 | TOPDOME-SHEEL | SS316L | 01NO. |

| 03 | BOTTOMDOME- DISH | SS316L | 01NO. |

| 04 | BOTTOM DOME GASKET RING | SS316L | 01NO. |

| 05 | BALL VALVE | SS316L | 01NO. |

| 06 | TROLLEY BASE | SS304 | 01NO. |

| 07 | CASTERS (FIX & SWIVEL) | PUCASTORS | 04NOS. |

| 08 | HANDLE FOR TROLLEY | SS304 | 01NO. |

| 09 | MOTOR | 01NO. |

| Model (Dia X No Of Plates) | Height Of Plates (mm) | Filtering Area (MM²) | Cake Holding Cap. (Ltrs) | Flow Rate Ltrs/Hr | Pump Size | Motor Rating (H.P.) |

|---|---|---|---|---|---|---|

| 8”X 6 | 25 | 0.2 | 4.2 | 450” 500 | 1" | 1 |

| 8”X 8 | 25 | 0.26 | 5.6 | 550 - 650 | 1" | 1 |

| 14” X 8 | 40 | 0.72 | 22.5 | 1300 - 1500 | 1" | 2 |

| 14” X 10 | 40 | 0.93 | 29.1 | 1600 - 1800 | 1" | 2 |

| 18” X 12 (s) | 28 | 1.85 | 67.2 | 4000 - 4500 | 1.5" | 3 |

| 18” X 15 (s) | 28 | 2.3 | 37.5 | 5000 - 5500 | 1.5" | 3 |

| 18” X 23 (s) | 28 | 3.4 | 53.55 | 7700 - 8200 | 1.5" | 3 |

| 18” X 8 (D) | 40 | 1.32 | 47 | 2700 - 3200 | 1.5" | 3 |

| 18” X 12 (D) | 40 | 1.84 | 67.2 | 4000 - 4500 | 1.5" | 3 |

| 24” X 12 | 40 | 2.98 | 110 | 6800 - 7300 | 2” | 5 |

| 24” X 15 | 40 | 4.4 | 123 | 10200 - 10700 | 2” | 5 |

| 24” X 23 | 40 | 6.9 | 130 | 16000 - 16500 | 2” | 5 |

| 33” X 14 | 40 | 7.2 | 210 | 14000 - 15000 | 2.5" | 7.5 |

| 33” X 20 | 40 | 11.65 | 240 | 19500 - 20000 | 2.5" | 7.5 |