Agitator Tank: Efficient Mixing for Industrial Applications

An Agitator Tank is a specialized vessel used for blending, mixing, and homogenizing liquids or materials in industries such as pharmaceuticals, chemicals, food processing, and wastewater treatment. Equipped with an agitator or impeller, these tanks ensure uniform distribution of substances while preventing sedimentation or phase separation.

Features and Functionality

High-Quality Construction: Made from stainless steel 316L, 316, 304, 304L ensuring durability and corrosion resistance.

• Efficient Mixing System: Features paddle, propeller, or turbine agitators to achieve desired consistency and uniformity.

• Variable Speed Control: Allows users to adjust the mixing speed based on the material’s viscosity and process requirements.

• Sealing & Insulation: Designed with leak-proof seals and thermal insulation for applications requiring temperature control.

• Customizable Capacity: Available in various sizes, from small laboratory-scale tanks to large industrial mixing vessels.

Applications

Agitator tanks are widely used in industries such as food and beverage, chemical processing, pharmaceuticals, cosmetics, paints, and wastewater treatment, ensuring precise and uniform mixing of components for production processes.

Benefits of Using a Agitator Tank

✔ Enhances product consistency and quality

✔ Prevents material separation and sedimentation

✔ Reduces manual mixing efforts, improving efficiency

✔ Adaptable for various industrial applications

A well-designed agitator tank optimizes mixing operations, ensuring homogeneous product formulation for industries requiring high standards of consistency and reliability. Whether for liquids, powders, or slurries, it is a vital component in any manufacturing process demanding precision and efficiency

Related products

Disposable Wate Trolley

Draintrap

SS-Ladder

SS-Lockerr

SS-Trolley

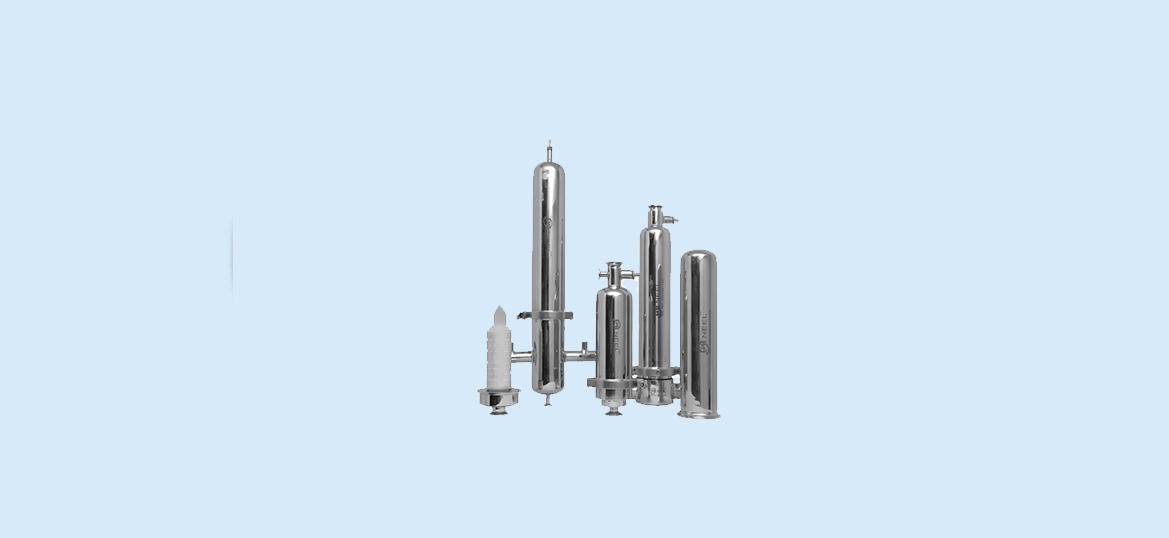

Filter-Housing

Cage-Trolley

Agitator-Tank

SSC-Hair

Crossover Bench

Manhole

Dynamic Pass Box